To Help Reduce Drug Shortages, We Need Manufacturers to Sell Quality — Not Just Medicine

By: Janet Woodcock, M.D., Director, Center for Drug Evaluation and Research

You might not always shop based solely on the lowest price. For instance, if you highly value your time, you may choose a car from a manufacturer with a great reputation for reliability, even though similar cars cost a bit less. Choices based on what you value are common in everyday life. But, unfortunately, when it comes to prescription medications, buyers may not have that option. And in the view of the U.S. Food and Drug Administration, this lack of transparency is contributing to ongoing drug shortages, a critical health care issue that reduces treatment options, limits access to medications, and can threaten the well-being of patients in need of important therapies. Let’s take a closer look.

All drug manufacturers that sell their medications in the United States must adhere to the FDA’s Current Good Manufacturing Practice (CGMP) requirements. Adherence to CGMP requirements is intended to make sure the drug itself is of adequate quality.

But there’s another element to quality in manufacturing — the ability to reliably make the product in sufficient quantities and with sufficient speed to ensure that supply consistently meets demand over sustained periods of time. This is especially true in the pharmaceutical industry, where the product is often life-sustaining — and ongoing access is critical.

Purchasers of prescription drugs such as drug distributors, hospitals, and pharmacies can be assured that FDA-approved medicines have been shown to be safe and effective for their labeled uses. Since these purchasers have tight budgets, they may select the lowest-priced product, in the absence of any other information. Also, they will often commit to purchasing many drugs covered within a single contract, placing pressure on each drug in that contract to be sold at the lowest price possible. So, several features of the modern market focus purchasers solely on price. But if purchasers also had the option to pay for reliable production, they might be willing to pay more for a medicine from a manufacturer with a proven track record of prompt and regular delivery of product, in order to avoid shortages.

Manufacturers with very high reliability usually have what is called a mature quality management system. However, purchasers currently are not able to readily identify those manufacturers. With today’s regulatory landscape, buyers actually have very limited information linking the medicine they buy with the facilities in which it was manufactured, other than the knowledge that the product was made under CGMP.

Lack of information about which companies have mature quality management systems means that buyers of pharmaceuticals are unable to reward drug manufacturers that have these extra, and valuable capabilities. Unfortunately, incentives today are not high enough for many manufacturers to establish mature quality management capabilities. As a result, drug manufacturers are more likely to keep costs down by minimizing investments in manufacturing quality, leading to quality issues that can trigger supply disruptions and shortages of needed medications.

There are many reasons for drug shortages. This shouldn’t be one of them. The FDA has been exploring a potential solution.

The FDA’s Task Force on Drug Shortages supports the idea of a rating system that could be used to inform purchasers, group purchasing organizations (GPOs) for health care systems, and even consumers, about the quality management maturity of the facilities making the drugs. This idea envisions that pharmaceutical companies could, at their discretion, disclose the rating of the facilities where their drugs are manufactured. Should they choose to disclose this rating, group purchasing organizations and other purchasers could require disclosure of the rating in their contracts with manufacturers. This effort would introduce transparency into the market, and provide companies committed to quality management maturity with a competitive advantage, potentially enabling them to obtain sustainable prices as well as grow market share.

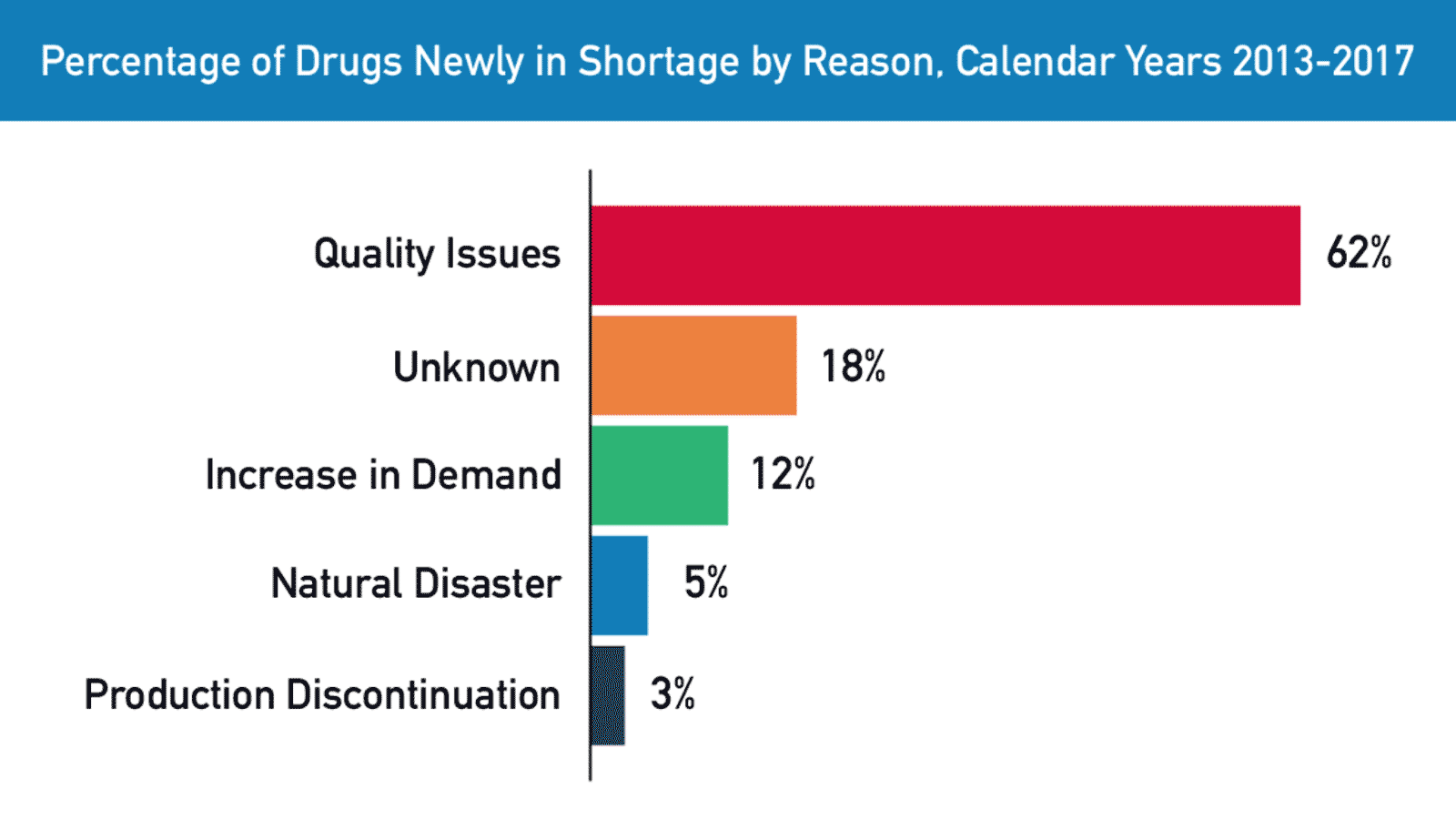

Analysis of recent drug shortages indicates the need for rewarding more investment in quality. A team of FDA economists examined a sample of 163 drugs that first went into shortage between calendar years 2013 and 2017. They found that of the 163 drugs in shortage, 62 percent went into shortage after supply disruptions that were associated with manufacturing or product quality problems. Another 18 percent went into shortage for unknown reasons, and much smaller percentages were associated with unanticipated increases in demand (12 percent), natural disasters (5 percent), or product discontinuations (3 percent). The chart below illustrates these findings. Based on these proportions, whatever we can do to help reduce shortages related to manufacturing quality issues will be worthwhile.

Most drugs in shortage were experiencing supply disruptions, specifically quality issues.

Source: FDA

Of course, no single effort will be enough to prevent drug shortages. The FDA is working on many other solutions. In fact, we will soon release a report focusing on the root causes and potential solutions to drug shortages. In June 2018, a bipartisan group of 31 U.S. Senators and 104 members of the House of Representatives asked the FDA for assistance in addressing the Nation’s ongoing drug shortage issues. In response, we convened the Task Force to study the problem and generate innovative solutions. In the coming days, the FDA will issue a special report discussing a variety of ideas for solutions to drug shortages.

Lasting and meaningful solutions to drug shortages will require collaboration and cooperation among all stakeholders. The FDA looks forward to our continued work with legislators, industry, health care professionals, other agencies, purchasers and purchasing organizations, academia, patients and many others to help ensure consistent and safe access to needed medicines for the American public.